Custom Foam Inserts

An optional extra for the inside of your waterproof case, custom foam inserts are manufactured to fit the precise shape of your equipment, enhancing appearance and boosting protection.

Why do cases need custom foam?

Standard pre-cubed foam is an option for most waterproof cases, but custom foam is different. It's a thoroughly bespoke option that provides a higher level of protection for your equipment - and takes presentation to the next level!

Protective

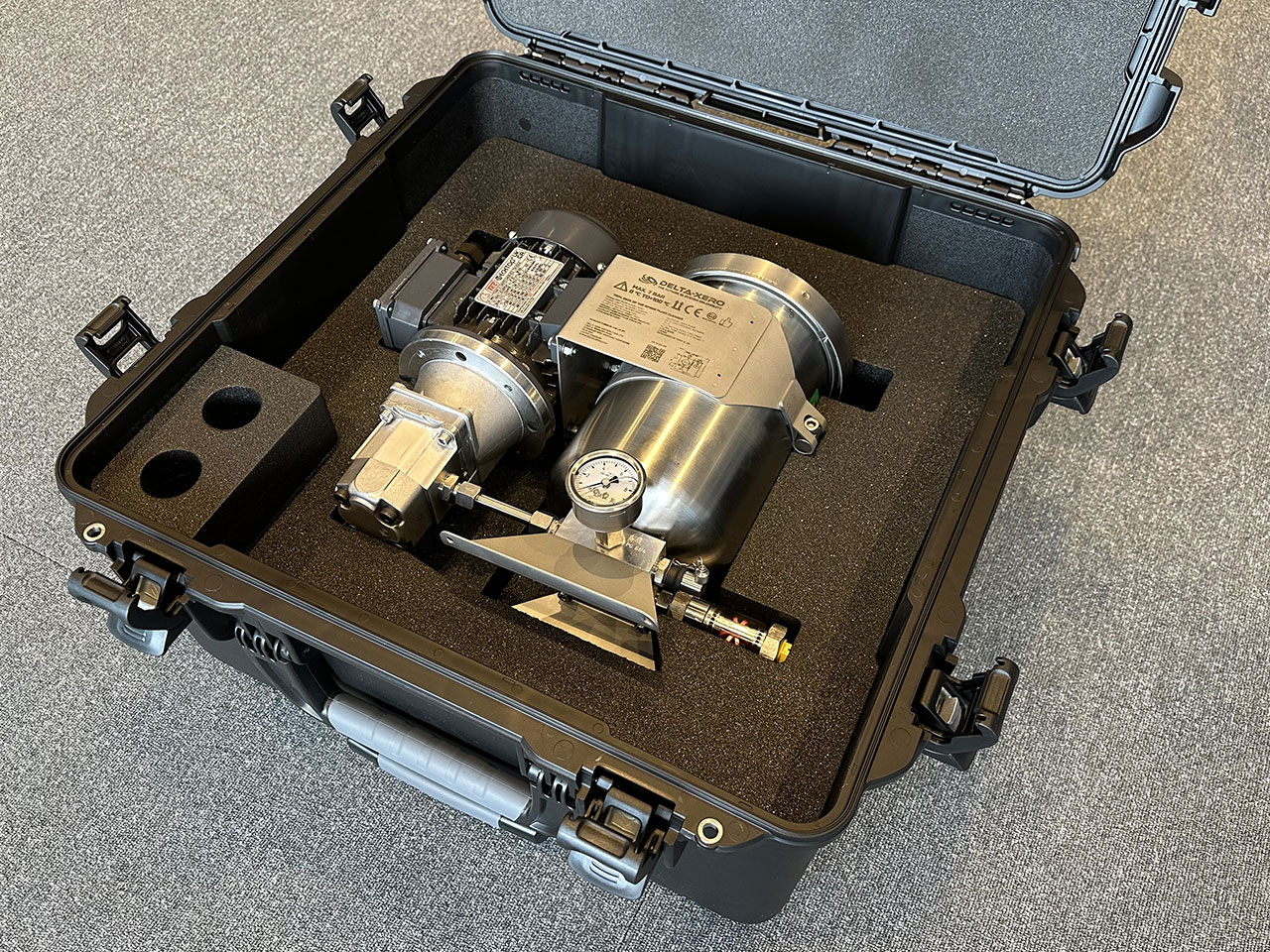

Foam plays a pivotal role in protecting the contents of your case. A custom foam insert gives your equipment the extra cushioned protection it needs while in transit and helps to protect your items against shock and vibration as well as unexpected mishandling.

Attractive

Custom foam allows us to do much more with the way your products are presented. It's a great way to make a powerful first impression, and particularly useful for showcasing product samples. A colour-coordinated and well organised interior can make all the difference.

Organised

Whatever your case holds - tools, samples, instruments - it helps to be able to see where everything is. Shadow foam uses contrasting colours for the foam's surface and cavity to make it easier to spot any missing items, so you don't forget to pack something away.

Explore the possibilities

There are many things we can do with custom foam inside a Peli, Nanuk or Explorer case to make it the perfect solution for your equipment and your business. Here are just a few...

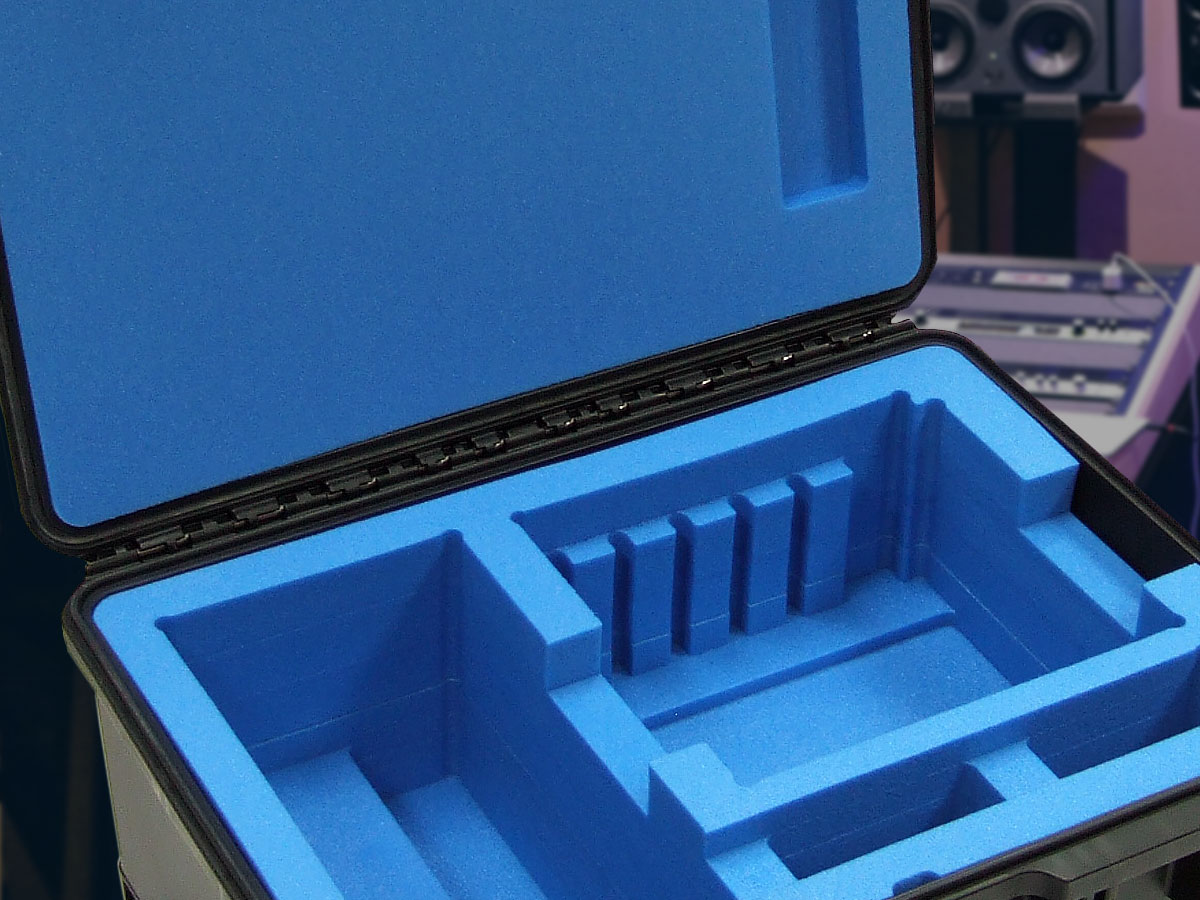

Stackable Layers

Cases can contain multiple layers of foam, stacked one on top of the other, making good use of available space and helping to protect and organise your equipment.

Lid, Base or Both

Custom foam can be fitted into the base, the lid, or both, keeping your valuable products organised and giving them all-round cushioned protection.

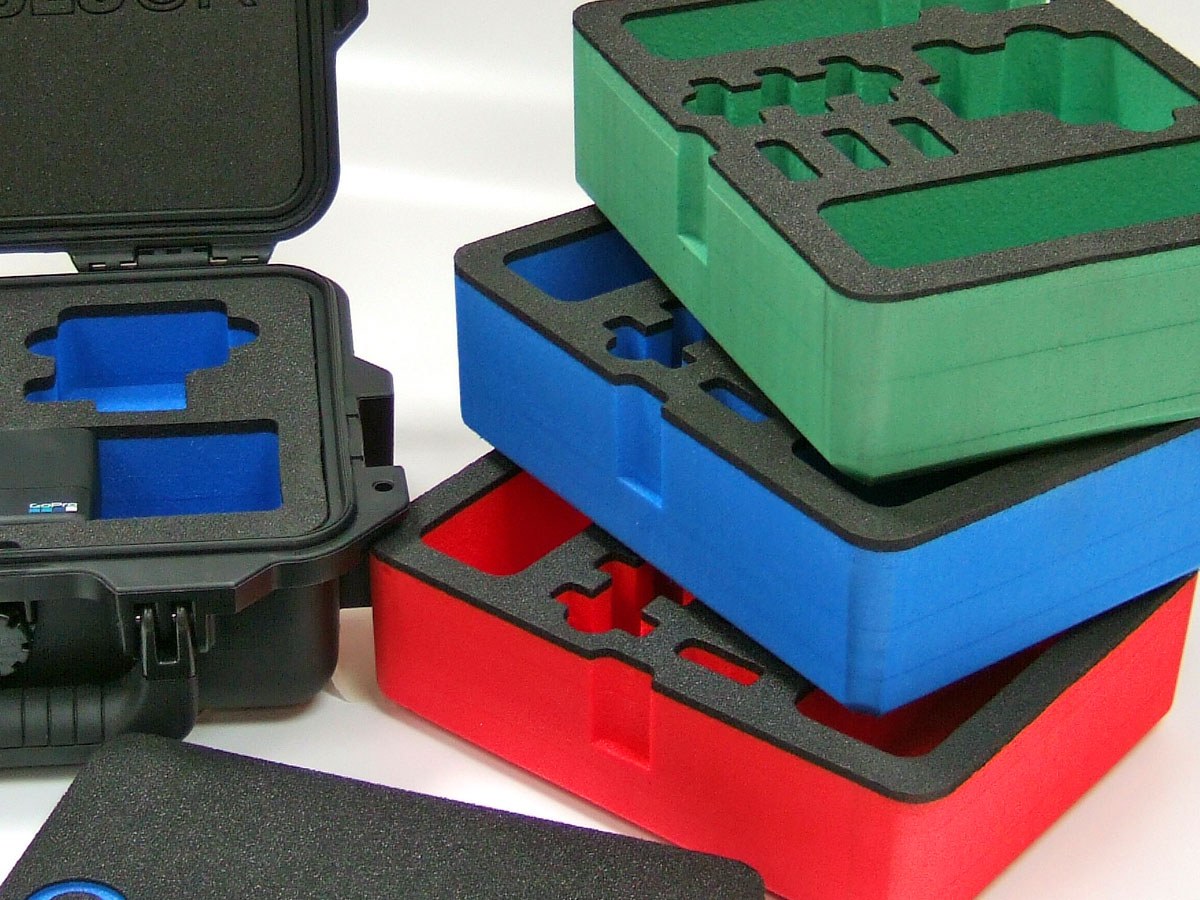

Different Colours

You're not limited to grey or black. A range of different coloured laminated foams can be chosen to reflect your brand and complement the case's outer shell.

Foam + Graphics

Foam inserts can be combined with graphics to create a fully bespoke case. Graphics can be applied to the foam, any panels and the internal or external case shell.

Shadow Foam

You can have the top layer of foam a different colour to the cavity. This technique - also known as colour contrasting - is a useful way to identify missing items.

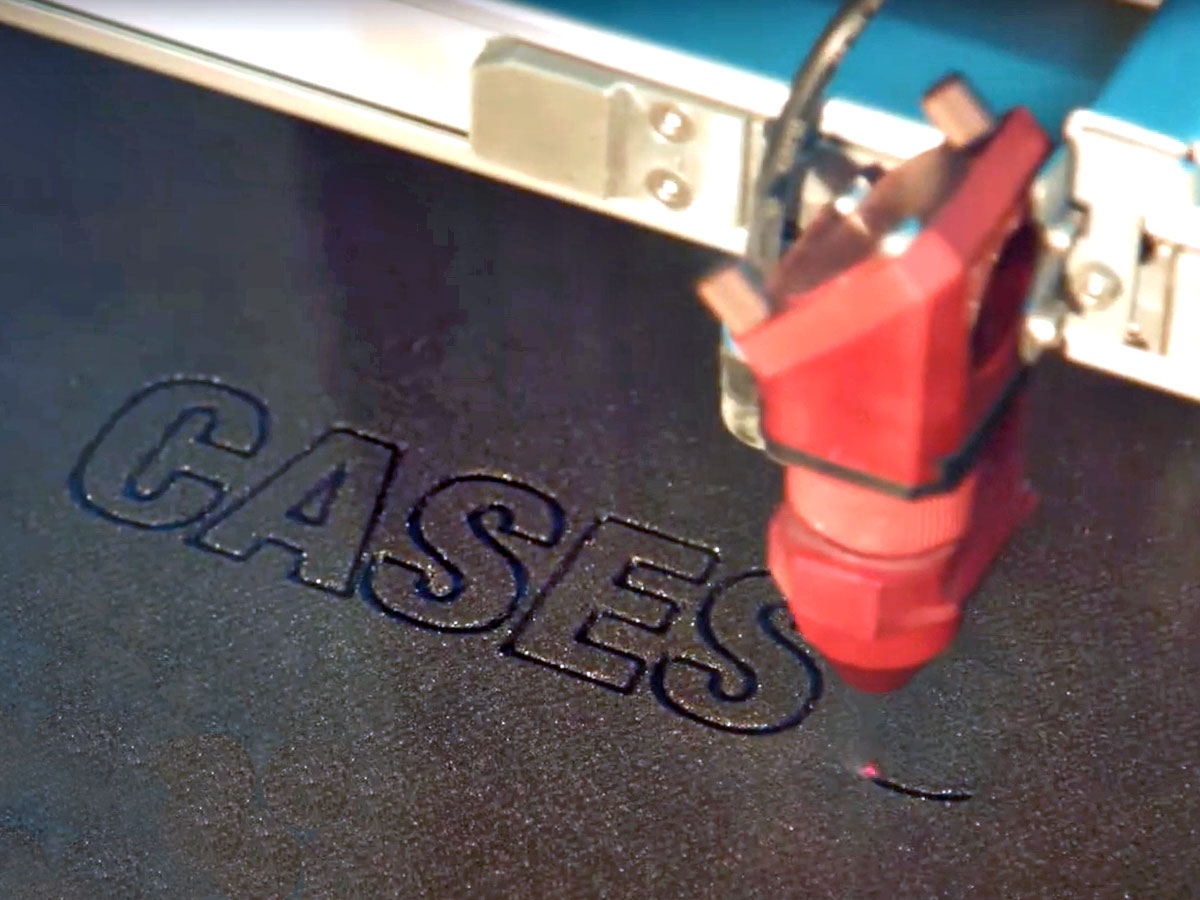

Laser Etching

Why not let us extend your brand from the outside in with individual shapes and logos expertly laser-etched into the foam. We can even engrave text.

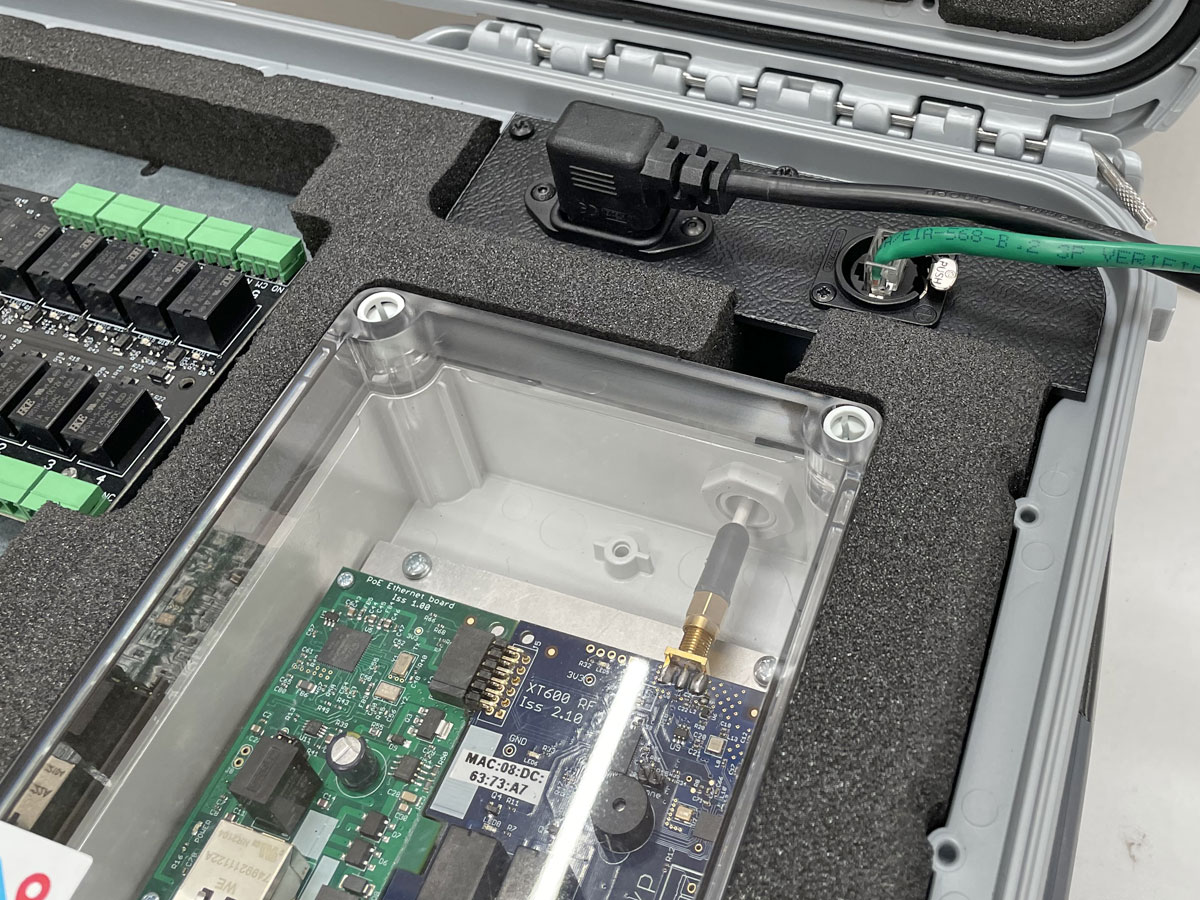

Panel Integration

Custom foam can be combined with hard plastic inserts and printed panels to create the perfect sales or demonstration case for your samples and instruments.

Electronics

Whether it's for lighting or charging, we can incorporate electronic circuitry alongside the inserts for a truly functional and eye-catching case solution.

Specialist Foams

We can use specialist materials such as ESD-safe anti-static foam to protect sensitive electronics and clean room environment foam which is low shedding.

Unsure of what you need?

Our experts here at Cases UK can guide you in the right direction and help you find the perfect solution for your business. Get in touch today - we'd be happy to offer advice.

How the process works

Some of you approach us with a full brief and know exactly what you want. Others are less sure, and seek our advice on the best solution. Whatever your level of knowledge, we can work with you.

- 1

We start by ensuring we have a good understanding of the products that will go inside the case. Ideally, you'll send us the products or physical replicas. However we recognise that this isn't always possible. For this reason, we also accept CAD files. From here, we're able to assess the size, weight and fragility of the items. We also explore the functionality of the products and consider how and where the case will be used.

- 2

If you've requested our advice, we start to develop a solution. Having a solid understanding of the products enables us to make decisions about ease of packing and demonstration, levels of hygiene or sterility, electrical components and so on. Our service also includes design and marketing whereupon the case solution can be influenced by your branding.

- 3

We provide an initial quote and design brief. Cost is an inevitable factor in any project, but custom cases can be more affordable than you think. Once we have identified the appropriate solution, we provide a quote which includes costs, design details, and manufacturing timescales.

- 4

Upon accepting the quote, we produce a CAD drawing. This is emailed to you to give you a clearer idea of what you will be receiving. Changes may be requested at this point and we can iron out any potential design issues, both from your perspective and ours. Once the design has been signed off, this becomes the master copy. (Any subsequent orders can be made from this design for years to come.)

- 5

The CAD master copy is sent to our manufacturing facility where it enters production. Typically this incorporates multiple stages and processes, depending on the products and services involved. You will be notified when your order is ready for dispatch.

Cutting edge technology

Our highly skilled in-house team use a variety of techniques to craft the perfect custom foam insert for your waterproof case.

CNC Machining

Pre-programmed software enables us to cut, shape, and create foam inserts to an ultra high level of precision.

Water Jet Cutting

We can use high pressure jets of water to cut extremely complex designs to a high degree of accuracy.

Die Cut Shaping

Die cutting is an efficient and affordable way to create simple, high volume foam inserts of various shapes & sizes.

Laser Etching

Logos, patterns and more can be engraved into foam to create eye-catching results with a crisp, sharp finish.

Design & marketing expertise

Our in-house designers use high end FARO® technology for 2D and 3D scanning, and the latest CAD software including AutoCAD® and SolidWorks® to design the optimal foam solution for your case.

Maximum protection lies at the heart of the process, but alongside this, we also carefully consider factors such as ease of access, environmental needs and of course presentation, which includes your logo and branding.

Once the design has been signed off, the CAD drawing is transferred into our CAM (computer-aided manufacturing) system to be converted into machine code ready for production.

Examples of custom foam inserts

Custom foam interiors can be created for all kinds of applications and industries. We can work with any waterproof case including those from Peli, Storm, Nanuk, Explorer and more. Below is a small selection of foam inserts to give you an idea of what's possible. If you'd like anything similar, get in touch, we'd be happy to discuss your requirements.

Why choose Cases UK?

Trusted by top brands

Questions

Where possible, we like to receive your products - or exact replicas - so that we have physical objects to work from. This allows us to evaluate the best way to profile your items so that they receive maximum protection and gives us an easy way to test that they can be removed from the foam ergonomically.

However, we accept that providing physical products is not always possible, and for this reason we also accept CAD files. If sending CAD files, do remember that any mistakes in these can prove costly, so please double-check that the files you send us are accurate. Even the smallest bolt or screw protruding from the physical item, if not included in the CAD file, risks causing unsightly damage to the foam.

For the majority of jobs, a prototype is not required. Our design team will supply a 2D PDF drawing of the layout and we can discuss this with you, together with any changes required, before anything is manufactured. Once the drawing has been signed off and moved to the manufacturing stage, our production staff will work from the master design. That said, we are able to supply prototypes if required, but this is dependent on the overall size of the project.

We always try to work to your timescale, however it depends largely on the complexity of the final design. If it's a relatively simple design and a short production run, we can normally fit this in between our larger production runs. We have multiple production machines at our UK manufacturing facility so we have the capacity to work on many orders at the same time.

Using our 30 years of extensive knowledge in the packaging industry, our in-house designers will choose the optimum material to protect your items in transit while also complementing their appearance, resulting in an overall design that's both protective and aesthetically pleasing. Foam is measured by its density and there are many different grades, so you can be assured that there will be one suitable for your needs.

All of them! Because we manufacture all of our custom foam in our own manufacturing facility, we are not limited to any particular shape or size. We can even supply custom foam not destined to go inside an enclosure, from a simple foam plug to an entire suspended ceiling. There are virtually no limitations to what we can manufacture!

Find out more

Get in touch and tell our experts about your requirements so that we can find the perfect solution for your needs.